::: LT-310 :::

Experimental device for monomolecular film deposition

according to the Langmuir—Blodgett (LB) and similar techniques

DESCRIPTION

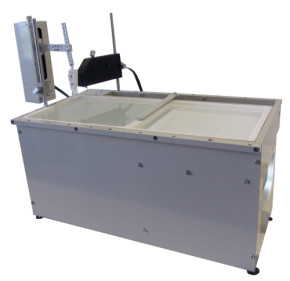

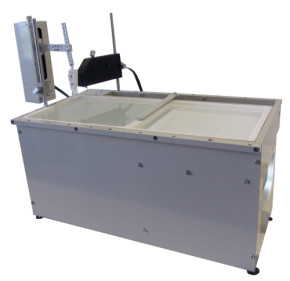

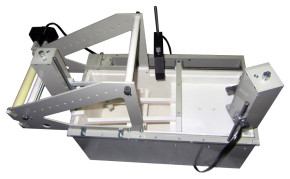

Experimental device

for film deposition LT-310

with installed

additional

units and accessories.

LangmuirBlodgett trough LT-310 is experimental research apparatus intended for deposition of mono- and multimolecular films according to the LangmuirBlodgett (LB) and similar techniques. It is also suitable for deposition of thin layers of various nature on solid substrates. Additional units and accessories enable the monomolecular layer deposition for versatile substrate types: a winding unit realizes deposition of LB layers onto flexible substrates (tape) and onto flat rigid substrates attached to the winded tape; rig for horizontal precipitation allows to deposit monomolecular layers onto submerged substrate according to Langmuir-Schaefer (horizontal precipitation, HP) technique by the liquid level lowering (draining).

LT-310 can be applied for

- application of monomolecular films

on solid samples according to the Langmuir-Blodgett (LB) technique or to the horizontal

precipitation (HP) technique

- deposition of multimolecular

films using corresponding layer-by-layer technique

- formation of mono- and multimolecular composite coatings on solid surfaces

- modification of the surface properties (hydrophilic behavior, optical,

electrical properties etc. )

- fundamental research in ultrathin film fabrication and their use

as insulating and protective coatings, molecular electronic elements, in biology

for creation of bilayer lipid membranes etc.

FEATURES

DELIVERY SET

| Code |

Name |

Q-ty |

| LT-310-010 |

LB trough LB trough

|

1 |

| LT-310-020 |

Dipper

unit (Substrate clamping holder for fast fixing of flat sample on the dipper lever) |

1 |

| LT-310-030 |

Surface

pressure sensor |

1 |

| LT-310-040 |

Control

electronic unit1 |

1 |

| |

ADDITIONAL ACCESSORIES (OPTIONAL) |

|

| RT-01 |

A peristaltic pump for continuous feeding of the deposited film on the aqueous surface. Ready to be installed directly in the trough side wall. (Includes the case with rotor, stepper motor, silicone hose diam 2/4 mm, clamping rings) A peristaltic pump for continuous feeding of the deposited film on the aqueous surface. Ready to be installed directly in the trough side wall. (Includes the case with rotor, stepper motor, silicone hose diam 2/4 mm, clamping rings) |

1 |

| DT-03 |

A microdoser (syringe pump) for feeding the deposited film on the aqueous surface A microdoser (syringe pump) for feeding the deposited film on the aqueous surface |

1 |

| LT-310-060 |

A mounted unit for the tape substrate winding in set with guides. Two motors drive to wind and rewind the tape. A mounted unit for the tape substrate winding in set with guides. Two motors drive to wind and rewind the tape. |

1 |

| LT-310-050 |

A rotating barrier for the monomolecular film transfer into working (deposition) area A rotating barrier for the monomolecular film transfer into working (deposition) area |

1 |

| LT-310-030 |

Additional surface

pressure sensor Additional surface

pressure sensor |

1 |

| LT-310-070 |

Rig for film application by the horizontal precipitation method Rig for film application by the horizontal precipitation method |

1 |

Note:

1 Basic set also includes control software (for Win32) and operation manual.

Safety guides for LT-310 trough (pdf, 620 kB)

Examples of LT-310 configurations

* Host PC is not included in the delivery set

* Host PC is not included in the delivery set

Depending on the installed units and accessories, LT-310 apparatus may be configured in such variants (for example)

Conventional LB trough configuration includes horizontal barrier, surface tension sensor and dipper unit.

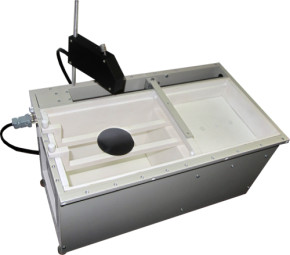

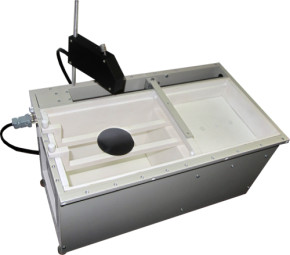

Configuration of the trough for horizontal precipitation includes horizontal barrier, surface tension sensor and specialized rig two Z-shaped PTFE bars with adjusting screw on one end. Draining hose(s) are employed in the technique. (Silicon wafer is shown as example of substrate placement).

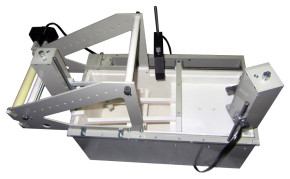

Configuration of the trough for deposition on tape substrate includes horizontal barrier, surface tension sensor and specialized rig for tape winding. In this example, the trough also includes peristaltic pump for automatic feeding of the deposited monolayer. Alternativelly, a syring pump (microdozing unit) may be also involved to automate replenishment of active substance in the liquid interface or operator may do it manually.

The trough configuration for deposition on tape substrate with additional options. It includes specialized rig for tape winding, two surface tension sensors, rotating barrier for precise replenishment of deposited monolayer, and a peristaltic pump for automatic feeding of the active substance to preparatory area. Alternativelly, a syring pump (microdozing unit) may be used instead of peristaltic pump. Default horizontal barrier is not engaded.

SOFTWARE

Software for LB trough control and data acquisition is a Win32

application running under OS Windows 95/98/Me/NT/2000/XP/Vista.

The software is built according to the modular scheme oriented to perform specific

application technique and provides all preliminary settings and calibration necessary

for the LB trough operation as well control over the systems (mechanisms of the

barrier movement and sample dipping/lifting) at the film application.

Acquired data can be saved in special format or text files and can be then

processed, visualized and analysed in the program itself or with third party software

(e.g. SurfaceXplorer package or Microsoft

Excel).

Minimal configuration of host PC (not included in the delivery

set): Celeron® 1.7 GHz, RAM 512

MB, HDD 160 GB, VRAM 64 MB, monitor 1024x768x32 bit, MS Windows®

XP SP2, 1 free USB port.

LB trough

LB trough  A

A

A mounted unit for the tape substrate winding in set with guides. Two motors drive to wind and rewind the tape.

A mounted unit for the tape substrate winding in set with guides. Two motors drive to wind and rewind the tape.  A rotating barrier for the monomolecular film transfer into working (deposition) area

A rotating barrier for the monomolecular film transfer into working (deposition) area Additional surface

pressure sensor

Additional surface

pressure sensor