|

::: Contacts »

|

::: SurfaceXplorer :::

Software

package for the SPM-data processing, visualization and analysis

with option for control over SPM NT-206 Acquisition of SPM-image of the sample surface is only first stage of its study. Next important task for researcher is correct interpretation of the recieved data. DESCRIPTION

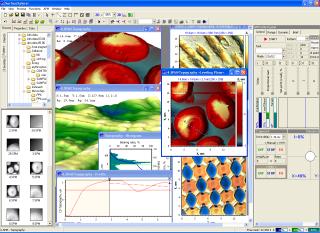

SurfaceXplorer is a 32-bit Windows-based program for visualization, processing and analysis of scanning probe microscopy data and additionally contains panel for control over SPM NT-206. SurfaceXplorer utilizes an OpenGL technology for image presentation and transformation that provides convenient and user-friendly on-line control over the visualization parameters. SurfaceXplorer' plug-in architecture provides flexible addition of new or updating of existing specialised functions for SPM-data processing. SurfaceXplorer is developed by reserachers experienced in SPM operation, SPM data interpretation and analysis. It means that user receives a balanced set of functions really important in work with the results obtained by SPM methods. FEATURES

SurfaceXplorer contains common set of functions usual for SPM data processing software (3D, 2D, 1D visualization, filtration, calculation of statistical parameters, sunlight simulation etc.) and includes advanced opportunities for the data presentation like flexible adjustment of the color palette, patterns of the surface drawing, on-the-fly zoom and rotation of a 3D image, etc. Plug-in linking option imparts to the program additional functionality. Below, listed are functions realized in the SPM-data processing unit of SurfaceXplorer program. Functions of SPM NT-206 control unit are cited in the instrument description. 1. Functions of SPM image visualization

2. Functions of SPM-image processing and transformation

3. Cross section functions

4. Calculation of statistic parameters of SPM image

5. Special functions

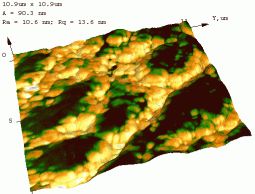

Additionally, SurfaceXplorer provides option for export SPM data files of other manufacturers. Special feature of the SurfaceXplorer software is an opportunity for direct joint analysis of SPM topography images and corresponding contrast images. In addition to their original function of the topography measurement, AFM's allow also mapping of lateral forces, phase shift, local electrical, magnetic and thermophysical properties as well as recording data of static and dynamic force spectroscopy. Analysis of distribution of the material properties over the surface and their comparison with the microgeometry helps to understand some intrinsic features of the materials and propose new ways in their improvement and reaching new preset performances. Joint 3D image (see Figure) can combine data of two types. One of them serves as a basic data set and it is rendered as a 3D SPM image. As a basic data set, different images can be chosen but topography image has among others a priority as it describes 'fundamental' characteristic spatial distribution of the material on the phase boundary within the scanned site. Secondary data set serves as a color table according to which points on the 3D image are colored. Contrast SPM images obtained simultaneously with the topography measurement are used as a secondary data set. So, the joint 3D image combines information from two data sets and directly visualizes distribution of specific characteristics over the scanned surface site. The figure shows that the joint analysis is especially useful at researching samples with heterogeneous properties, for example, composite materials.

Topography and phase shift map are rendered in joint 3D image: surface of a Diamond-like coating after friction. Initial surface is modified under friction that results in transition of constituent carbon into graphite form within spots of actual contact (the most protruded asperities). Dark color corresponds to sites with lower local elastic modulus. It means that the material on tops is softer than initial material of the coating (light color) in the valleys.

A unique function realized in the SurfaceXplorer package is elimination of height artifacts caused by the non-uniform material deformation by the AFM tip at scanning in Tapping Mode. The function takes into account real Young’s moduli of the materials found in the sample (upprer Figure) and corrects on topography image the height of the points within the scanned matrix taking information on local stiffness distribution from the corresponding phase shift image. As a result, a matrix of calculated differences in heights (Upper figure, b) is built in addition to the corrected topography image.

Cross section visualizing function includes a possibility to plot simultaneously

any number of similar (parallel) profiles from the same SPM data set. For example,

getting a profile from one image (e.g. topography), the software traces similar

profiles (by coorditaes in the surface plane) in all other data matrices existing

in the SPM data set. That function provides more precise measurement and analysis

of considered features on the image including comparison of the properties different

from topography data. Figure shows an example where profile from topography image

is plotted with the corresponding profile from the phase contrast image. Note

that some risen sites are softer than material in valleys.

EXAMPLES

|

Right image: an

example of joint analysis of topography and contrast

images with the software package SurfaceXplorer.

Right image: an

example of joint analysis of topography and contrast

images with the software package SurfaceXplorer.