|

::: Contacts »

|

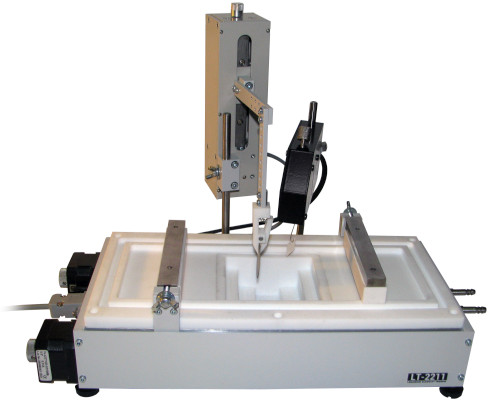

::: LT-2211 :::

An experimental device for deposition

of monomolecular films

according to the Langmuir—Blodgett (LB) technique DESCRIPTION

Langmuir—Blodgett trough LT-2211 is intended for

FEATURES

TECHNIQUES

DELIVERY SET

Note:

1 Basic set also includes control software (for Win32) and operation manual.

SOFTWARE

Software for LB trough control and data acquisition is a Win32 application running under OS Windows XP/Vista/7/8/10. The software is built according to the modular scheme oriented to perform specific application technique and provides all preliminary settings and calibration necessary for the LB trough operation as well control over the systems (mechanisms of the barrier movement and sample dipping/lifting) at the film application. Acquired data can be saved in special format or text files and can be then processed, visualized and analysed in the program itself or with third party software (e.g. SurfaceXplorer package or Microsoft Excel). Minimal configuration of host PC (not included in the delivery set): Celeron® 1.7 GHz, RAM 512 MB, HDD 160 GB, VRAM 64 MB, monitor 1024x768x32 bit, MS Windows® XP SP2, 1 free USB port. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||